WAREHOUSE AND INVENTORY MANAGEMENT SYSTEM

summary

Warehouse Management System (WMS) clearly understands the customer's warehouse operations so that it can quickly and accurately manage collection and payment flow, inventory changes, and inventory flow from receipt to shipment, and by suggesting alternatives, standardization and real-time monitoring of tasks are implemented to enable efficient operation.

Promotion Goals

- Main status and implications

-

Business operation aspect

- Lack of systematic work environment due to lack of integrated data management and interworking

- Increased business loss due to manual data management

-

Information operation aspect

- No analytical data and tools for business management and improvement

- Operating system for each task required for information management

- Construction goal

- ① Build a systematic work environment through work analysis and efficiency review

- ② Re-establishment and optimization of work standards through process inspection

- ③ Secure timeliness of information through accurate process inventory identification

- ④ Improved management level by securing data accuracy

- ⑤ Quick/accurate identification of corporate inventory information through matching logistics information

- ⑥ Increasing internal communication through system activation

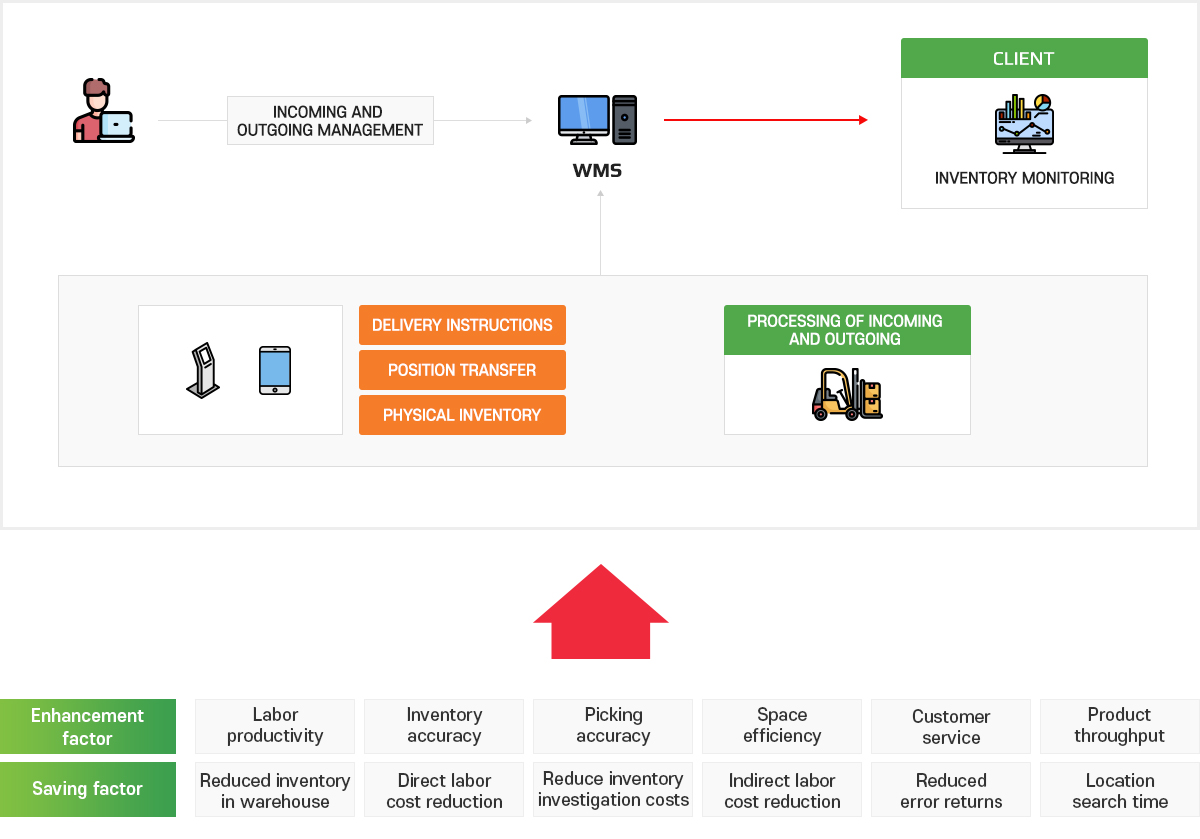

Expected Effects of Introduction

-

Cost savings

- Reduce logistics costs by standardizing work

- Reduce inventory costs with inventory management

- Increase profitability

-

Systematic quality control

- Accurate history management by product

- Product history and statistics management

- Providing quality control by manufacturers and suppliers

-

Application of technology

- Interworking between ERP or MES systems

- PDA (RFID) equipment application

- Maximize barcode utilization

-

Business processor

- Fast/accurate inventory management

- Secure transparency of the entire process

- Improve productivity by reducing time

- Standardization of processes

- Real-time logistics flow

- Maximize data reliability

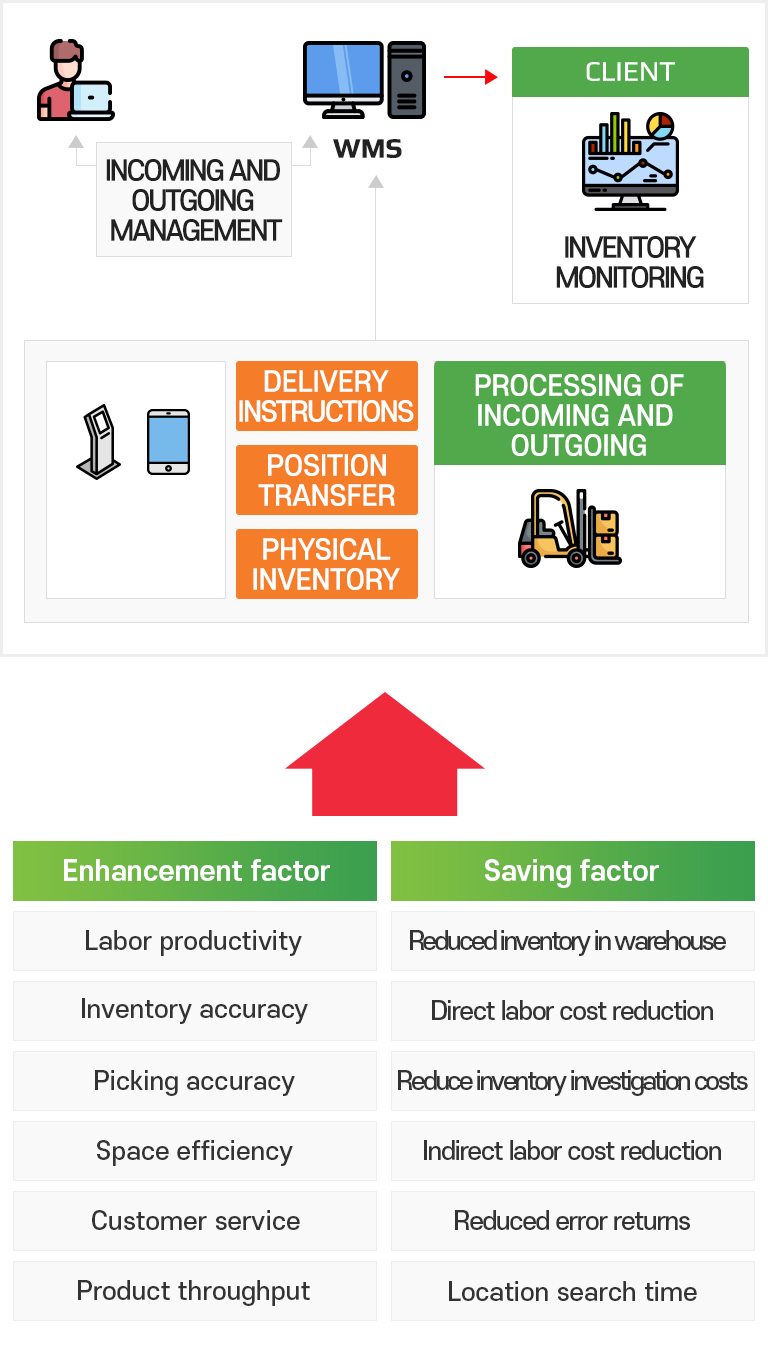

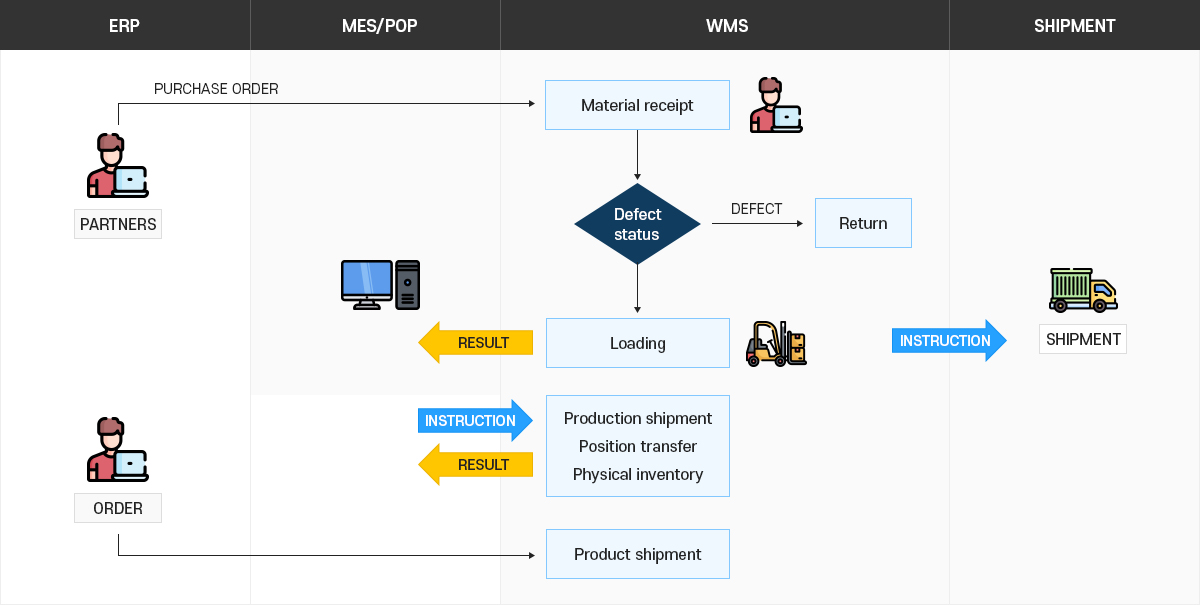

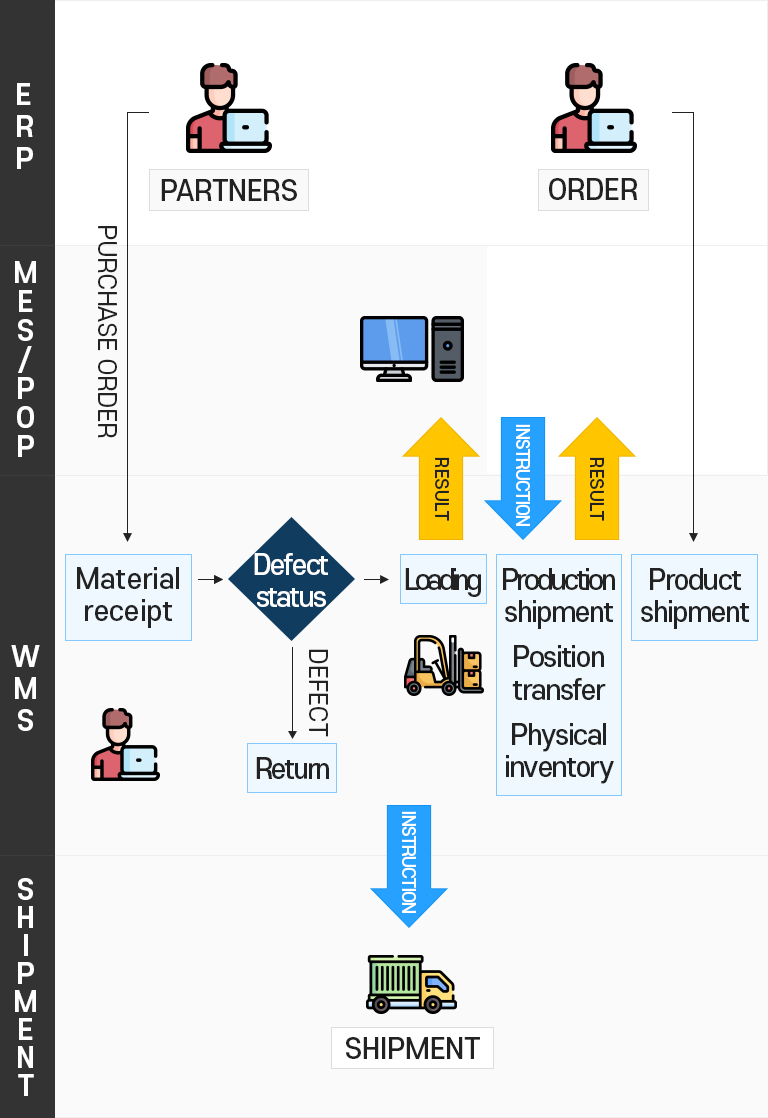

System Configuration

System Linkage Diagram

Program Function Configuration

-

Basic management

- Item code management

- Packaging unit management

- Warehouse code management

- Factory code management

- User management

-

Production management

- Purchase receipt

- Warehouse receipt

- Receipt status

- Return status

- Receipt real price management

-

Production process management

- Loading position management

- Pallet composition

- Pallet dismantling

- Label issuance

- Loading

- Zone management

-

Production management

- Inventory status

- Inventory status by loading location

- Pallet division

- Pallet merge

- Inventory status change

- Label issuance

- Physical inventory

-

Warehousing management

- In-house delivery

- Shipping management

- Picking

- Picking status

- Picking cancellation

- Sales delivery

- Delivery cancellation

- Waybill/ statement issuance

- Shipping history