ASSEMBLY LINE MANAGEMENT SYSTEM

Overview

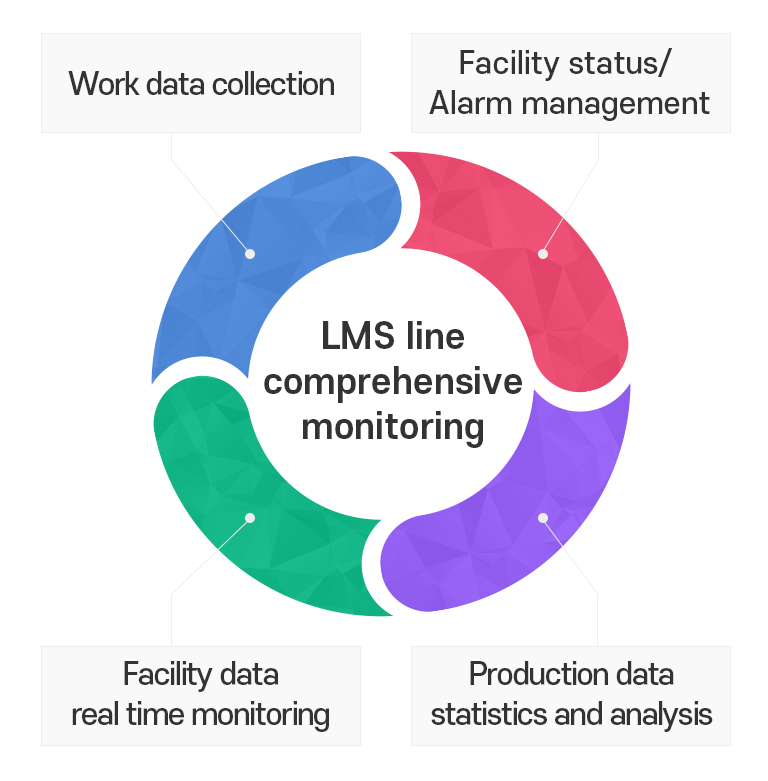

LMS (Assembly Line Management System) collects various assembly line information required in smart factories and can be interlinked with MES, and collects accurate work information to ensure the effect of production improvement.

TnLMS is a specialized solution for monitoring equipment lines, and is a solution that collects, analyzes, and visualizes equipment-related data in the construction of a factory automation monitoring system. Efficient facility management is possible by linking the collected information with MES, and efficient raw material management is possible based on the production data of each process.

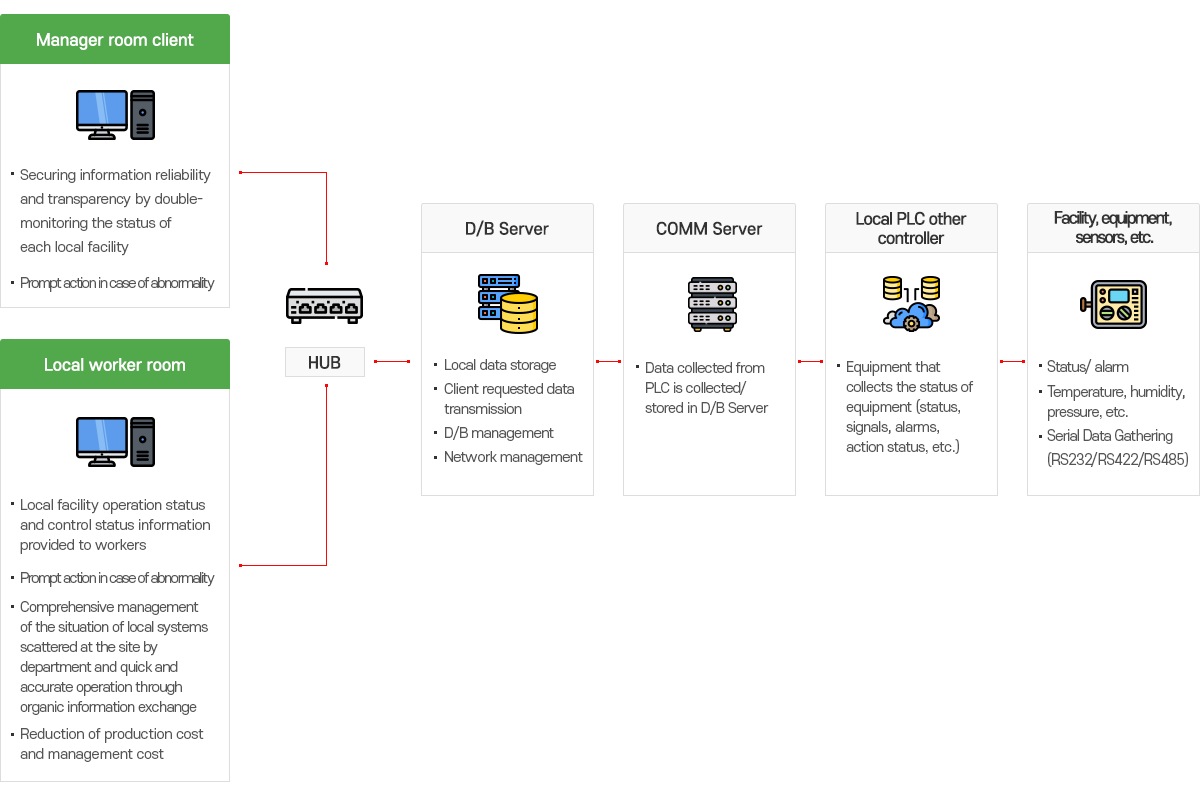

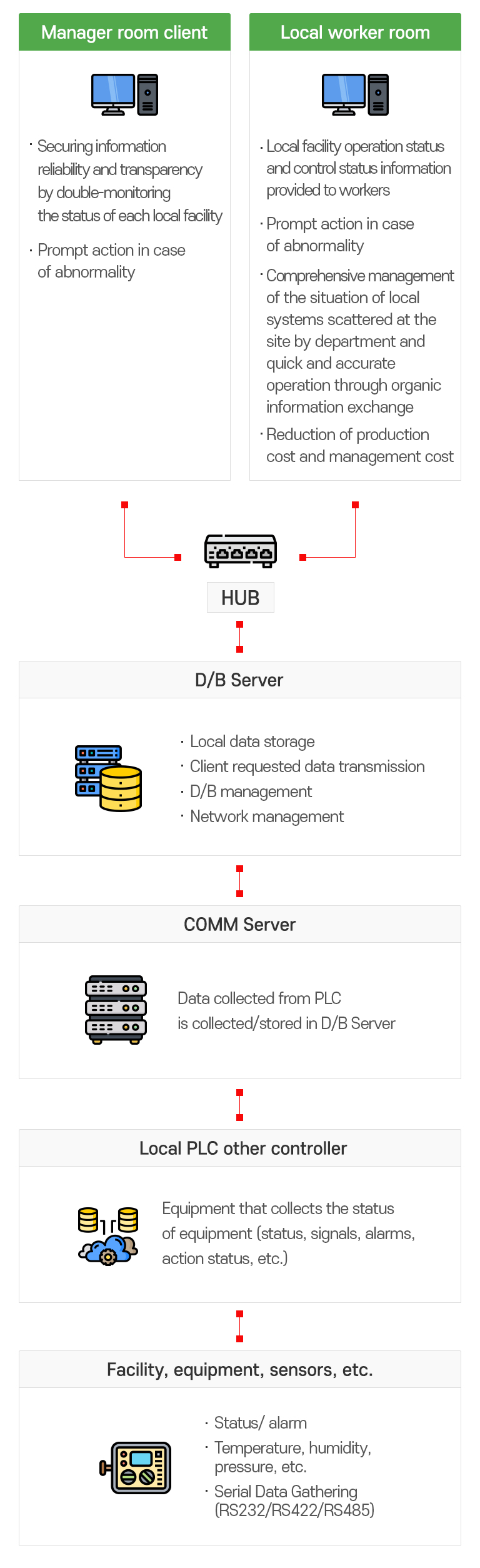

System Configuration

Main Functions

-

Line monitoring

- You can conveniently monitor information the displayed data sent from the process on the screen in real time.

-

Equipment alarm history

- It receives and manages various alarms occurring in the equipment.

- You can query the alarm history and use it for equipment management/analysis.

-

Production statistics and analysis

- It helps to analyze facilities and improve productivity by making production history and data into statistical data.

- Product defect rate can be easily identified.

-

Production history inquiry

- You can search history by equipment and item, so you can track individual products and search detailed conditions.

-

Interlink system management

- Data management is possible by linking equipment alarm history and history data in conjunction with the upper ERP or MES.

Features and Advantages

- Accurate production volume and production status can be identified.

- Various data of field information can be calculated through real-time collection.

- Efficient resource management is possible by utilizing production forecast information.

- Data requested by customers can be easily delivered.

- It is easy to prevent safety accidents through equipment abnormality alarm.

- It can grasp the condition of equipment in real time and prevent product quality degradation.